Research

Dissertation work

Sustainable inks for transistors

We investigated water-based inks with minimal post-processing requirements. We explored AuNP and PtNP contacts, revealing water-based inks do not degrade performance [1]. To achieve functional CNT channels, we used intermittent rinsing with water [11]. Finally, we studied crystalline nanocellulose (CNC), providing insights into its performance as a degradable ionic dielectric and the effect of nanocellulose form and surface groups on transistor performance [13].

3D microstructures for sensors

We employed aerosol jet printing to create conductive 3D graphene microstructures using water as the only solvent and without any post-print processing. Adding pillars to the humidity sensor degraded performance, contrary to past reports, whereas trusses improved sensitivity by adding a parallel conduction path to the sensing surface [7].

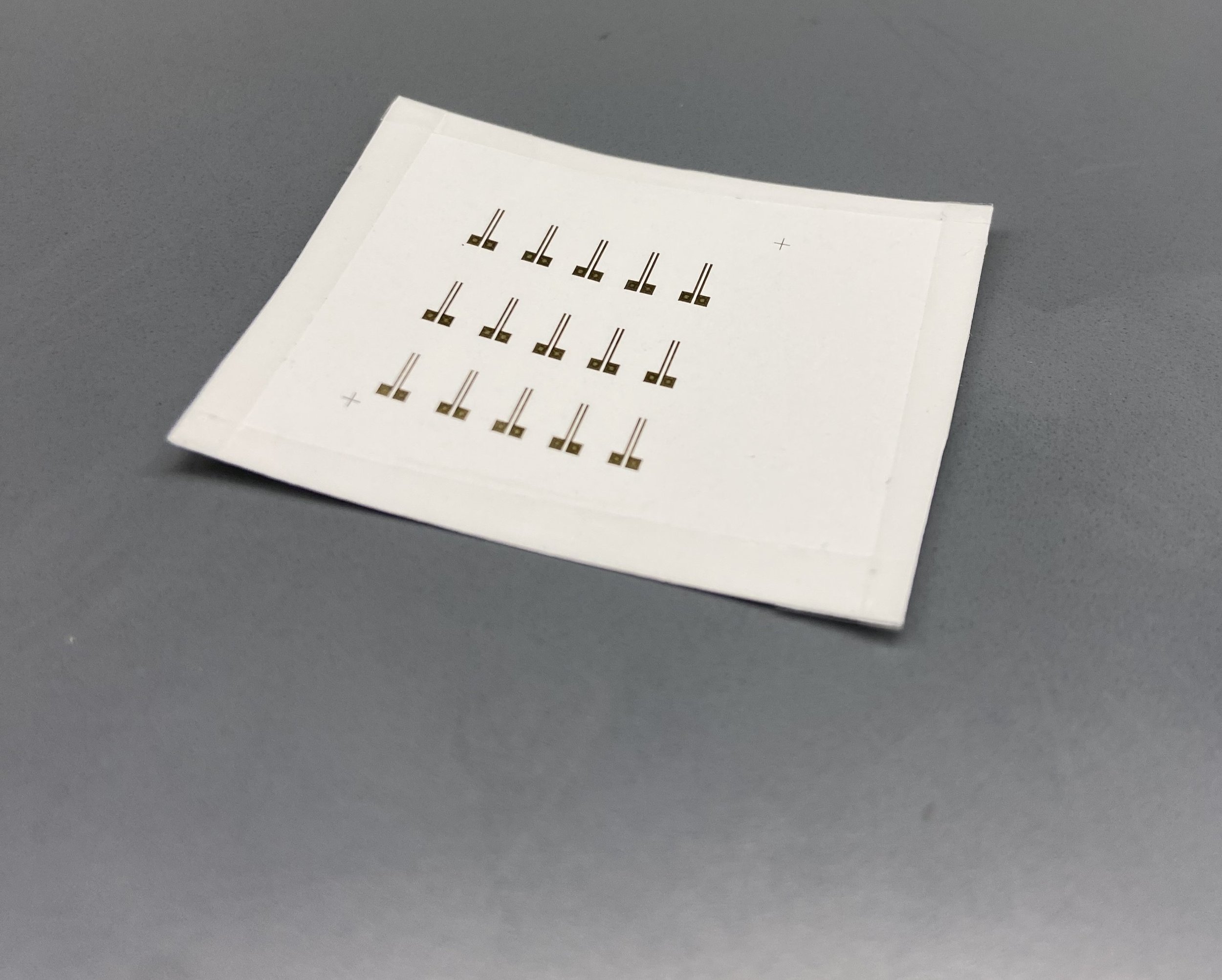

Capillary flow printing: sustainable + scalable transistors

We used a capillary flow printer to realize submicron channels for fully printed carbon nanotube transistors without using any chemical modification on Kapton, a flexible substrate, reducing process waste. The printed devices are competitive with SOTA TFTs for display backplanes with a shorter channel length and on a flexible substrate [2].

Future Work

Solution-Resistant Sustainable Printed Materials

Creating solvent-resistance printed electronics to enable applications such as:

Health + Environmental + Food monitoring

Underwater electronics (on boats, submarines, AUVs, even seals….)

Transportation vehicles

In window displays, antennas, and heaters

Tire pressure and lidar sensors

Printed On-Chip Microelectronics for Processing and Data Storage

Printing scaled logic and memory devices and arrays improve the mechanical robustness over hybrid devices and finally realize printed active electrical components for:

Wearable electronics and sensors (for humans, animals, plants, etc.)

Flexible displays (i.e. printed display backplanes)

Smart RFID tags for improved hardware security

Printed materials are ideal for space - lightweight, thin, often rad-hard, and replacements may be created in-flight. Some applications of printed electronics in space include:

Displays and sensors for health and environmental monitoring

Replace general electrical components with lightweight films